Floating dock plans are essential for a successful project. Step-by-step guides and detailed blueprints ensure safety and durability. Customizable designs suit various needs and water conditions.

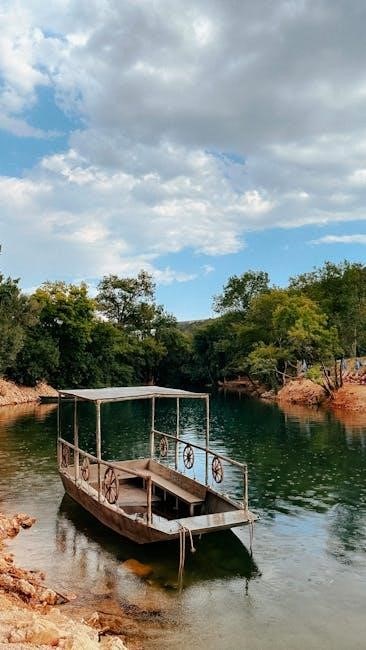

1.1 What Are Floating Dock Plans?

Floating dock plans are detailed guides that outline the materials, tools, and step-by-step instructions for constructing a floating dock. These plans often include blueprints, diagrams, and specifications to ensure the dock is safe, durable, and suitable for various water conditions. They cater to both DIY enthusiasts and professionals, providing customizable options to fit different sizes, shapes, and functionalities. Whether for residential or commercial use, floating dock plans help users build structures that maximize stability, buoyancy, and load capacity while adhering to safety and regulatory standards.

1.2 Importance of Using Detailed Plans

Detailed floating dock plans are crucial for ensuring safety, structural integrity, and compliance with local regulations. They provide clear instructions, minimizing errors and potential hazards. With precise measurements and material lists, plans help avoid costly mistakes and wasted resources. They also guide proper buoyancy and load calculations, ensuring the dock can support intended weights safely. Additionally, detailed plans often include maintenance tips and troubleshooting, extending the dock’s lifespan. By following these plans, builders can create a durable, functional, and aesthetically pleasing floating dock tailored to their specific needs and environmental conditions.

1.3 Benefits of Building a Floating Dock

Building a floating dock offers numerous benefits, including adaptability to fluctuating water levels and minimal environmental impact. It provides a stable and durable structure for recreational or functional use, enhancing waterfront accessibility. Floating docks are often more cost-effective than permanent structures and can be customized to fit specific needs. They also allow for easy relocation or modification, making them versatile for various water conditions. Additionally, floating docks can be designed with eco-friendly materials, ensuring long-term durability while blending seamlessly into natural surroundings.

Essential Materials for Building a Floating Dock

Pressure-treated lumber, durable decking materials, sturdy floats, and galvanized hardware are key components for constructing a reliable and long-lasting floating dock structure.

2.1 Pressure-Treated Lumber for the Frame

Pressure-treated lumber is a crucial material for building the frame of a floating dock, as it resists rot and insect damage in aquatic environments. Typically, 2×8 or 2×10 boards are recommended for the frame, ensuring durability and stability. This lumber is treated with preservatives to withstand moisture and prolong the dock’s lifespan. Properly sized and spaced, it forms the structural backbone of the dock, supporting the decking and floats. Choosing high-quality, pressure-treated wood is essential for a safe and long-lasting floating dock.

2.2 Decking Materials (Cedar or Composite)

Decking materials are vital for a floating dock’s surface, with cedar and composite options being popular choices. Cedar is durable, resistant to rot, and naturally insect-repellent, making it ideal for aquatic environments. Composite decking offers low maintenance, withstands moisture, and provides a sleek appearance. Both materials are durable and long-lasting, ensuring a safe and attractive walking surface. Cedar boards, such as 5/4 x 6 decking, are commonly used for their strength and aesthetic appeal, while composite materials offer modern convenience and versatility.

2.3 Floats (Plastic Barrels or Polyethylene Floats)

Floats are essential for providing buoyancy and structural support to a floating dock. Plastic barrels or polyethylene floats are commonly used due to their durability and water resistance. Plastic barrels are cost-effective and easy to source, while polyethylene floats are specifically designed for docks, offering superior strength and longevity. Both options ensure the dock remains stable and afloat. Properly securing floats to the dock frame is crucial for safety and performance, making them a critical component in floating dock construction.

2.4 Galvanized Hardware (Bolts, Brackets, etc.)

Galvanized hardware is crucial for securing the dock frame and ensuring durability. Bolts, brackets, and connectors are typically galvanized to resist corrosion from water exposure. These components provide structural integrity, holding the frame and floats together. Using galvanized hardware ensures long-lasting performance and protects against rust, making it a vital investment for any floating dock project. Properly tightening and positioning these elements is essential for stability and safety, ensuring the dock withstands various water conditions and heavy use.

Tools Needed for Construction

Essential tools include drills, impact wrenches, saws, wrenches, hammers, and tape measures. Safety gear like gloves and safety glasses is also crucial for safe construction.

3.1 Power Tools (Drill, Impact Wrench, Saw)

Power tools like drills, impact wrenches, and saws are indispensable for constructing a floating dock. Drills are used for making holes and driving screws, while impact wrenches securely tighten galvanized bolts. Saws, such as circular or reciprocating saws, are essential for cutting lumber and decking materials to precise measurements. These tools ensure efficient and accurate assembly of the dock frame and decking. Using the right power tools enhances safety and guarantees a sturdy, long-lasting structure. Proper handling and maintenance of these tools are crucial for a successful project.

3.2 Hand Tools (Wrenches, Hammer, Tape Measure)

Hand tools such as wrenches, hammers, and tape measures are crucial for assembling a floating dock. Wrenches are used to tighten bolts and secure hardware, while hammers drive stakes and fit parts together. Tape measures ensure accurate cuts and proper alignment of materials. These tools are essential for precise adjustments and manual tasks during construction. Having a well-organized set of hand tools streamlines the process, allowing for efficient assembly of the dock frame, decking, and float attachments. They are vital for achieving a secure and well-built structure.

3.3 Safety Equipment (Gloves, Safety Glasses)

Safety equipment, such as gloves and safety glasses, is indispensable when building a floating dock. Gloves protect hands from cuts, splinters, and abrasions while handling materials like lumber and hardware. Safety glasses shield eyes from debris during sawing, drilling, or hammering. These items ensure a safe working environment and prevent accidents. Wearing proper protective gear is a non-negotiable step in any construction project, especially when working with power tools and heavy materials. Prioritizing safety ensures a smooth and injury-free building process.

Design and Planning Considerations

Proper design and planning ensure your floating dock suits water conditions and intended use. Assess factors like water depth, wave exposure, and load capacity for optimal performance and safety.

4.1 Choosing the Right Design for Your Needs

Selecting the appropriate design for your floating dock ensures it meets your specific requirements and environmental conditions. Consider the intended use, such as fishing, swimming, or boating, as well as water depth and wave exposure. Dock size and shape should align with available space and functionality. Customization options, like railings or storage, can enhance practicality. Assessing local regulations and reviewing detailed plans helps match your dock design to the location. Proper design selection ensures durability, safety, and optimal performance for years to come.

4.2 Calculating Buoyancy and Load Capacity

Calculating buoyancy and load capacity is crucial for ensuring your floating dock remains stable and safe. Start by determining the dock’s total weight, including materials and intended load. Use the principle of flotation: the volume of water displaced must equal the weight of the dock. Floats or barrels should be sized to provide adequate buoyancy, with a safety margin. Consider water conditions, wave exposure, and maximum load. Detailed plans often include formulas or charts to simplify calculations. Proper buoyancy ensures the dock floats level and supports the intended weight without submerging excessively.

4.3 Permits and Local Regulations

Before constructing a floating dock, it’s essential to check local regulations and obtain necessary permits. Many areas require environmental impact assessments or zoning approvals. Ensure compliance with building codes, waterway restrictions, and environmental protections. Permits may be needed for structure size, material use, or water depth. Failure to comply can result in fines or removal of the dock. Research and consult with local authorities to ensure your project meets all legal requirements and minimizes environmental impact.

Step-by-Step Construction Guide

A step-by-step guide outlines the process from frame assembly to decking installation. Follow detailed plans to ensure safety and structural integrity. Each phase requires precision and care.

5.1 Building the Dock Frame

Begin by assembling the frame using pressure-treated lumber, ensuring all corners are square. Secure the frame with galvanized bolts, tightening firmly but avoiding over-tightening. Next, attach crossbeams for structural support, spacing them evenly for optimal weight distribution. Ensure the frame is level and sturdy before proceeding. Finally, prepare the frame for float attachment by installing necessary hardware, such as brackets, to secure the floats in place. Always follow safety guidelines and double-check all connections for stability and durability.

5.2 Attaching Floats to the Frame

Securely attach the floats to the dock frame using galvanized brackets and bolts. Position the floats evenly under the frame, ensuring proper buoyancy and balance. Tighten all hardware firmly to prevent shifting. Use plastic barrels or polyethylene floats for durability and resistance to water damage. Ensure the floats are spaced correctly to distribute weight evenly. Double-check all connections for stability and safety. Properly attaching the floats is crucial for the dock’s performance and longevity in water. Always follow the manufacturer’s guidelines for hardware and float placement to ensure maximum stability and reliability.

5.3 Installing Decking Boards

Begin by laying decking boards across the frame, ensuring they are evenly spaced and aligned. Use screws or nails to secure them to the frame, leaving slight gaps for water drainage. Cedar or composite materials are ideal for durability. Start from one end and work across, ensuring each board is tightly fastened. For multiple sections, overhang boards slightly to connect seamlessly. Sand rough edges for safety and finish with a sealant to protect the wood. Proper installation ensures a sturdy, weather-resistant surface for years of reliable use.

5.4 Adding Railings and Safety Features

Install railings to enhance safety and stability, especially for users needing support. Use galvanized or stainless steel hardware to secure railings to the dock frame. Posts should be at least 3 feet tall, spaced no more than 6 feet apart. Add safety features like non-slip coatings or textured surfaces to prevent slipping. Consider attaching dock cleats for securing boats and bumpers to protect the dock from impact. Ensure all components are tightly fastened to withstand water movement and heavy use. Regularly inspect railings and features to maintain reliability and safety for everyone using the dock.

5.5 Connecting Multiple Dock Sections

To connect multiple dock sections, use galvanized hinges or connectors for flexibility. Align sections carefully and secure with bolts or brackets. Ensure the connection is watertight to prevent movement. Use rubber spacers or pads to reduce friction and noise between sections. For added stability, attach cross-bracing or support beams. Regularly inspect connections for wear or loosening. This ensures a sturdy and cohesive structure, allowing the dock to expand or reconfigure as needed while maintaining safety and functionality for users.

Hardware and Accessories

Dock bumpers, cleats, and mooring supplies are essential for protecting and securing the dock. Galvanized hardware ensures durability, while connectors and bolts provide structural integrity and longevity.

6.1 Dock Bumpers and Cleats

Dock bumpers and cleats are crucial for protecting the dock from boat impacts and securing vessels. Bumpers, made from durable materials like rubber or PVC, absorb shock and prevent damage. Cleats, typically heavy-duty metal or composite, provide secure mooring points for ropes and lines. Proper installation ensures stability and safety, while high-quality materials withstand harsh marine conditions. These accessories are essential for maintaining the integrity and functionality of the dock, ensuring safe and reliable boat tie-offs in various water environments.

6.2 Mooring Supplies and Tie-Offs

Mooring supplies and tie-offs are essential for securing boats and ensuring dock stability. Durable ropes, lines, and shackles are commonly used to tie off vessels, while springs and snubbers help absorb tension. Properly installed cleats and mooring whips provide additional security, especially in windy or high-traffic conditions. High-quality materials resist corrosion and wear, ensuring long-term reliability. These components are vital for safe and efficient boat docking, protecting both the dock and the boats from damage caused by movement or harsh weather conditions.

6.3 Dock Bolts and Connectors

Dock bolts and connectors are crucial for securing dock sections and ensuring structural integrity. Galvanized or stainless steel bolts are recommended for durability and corrosion resistance. Connectors like dock hooks, clamps, and brackets provide stability and flexibility, allowing dock sections to expand and contract with water level changes. Proper installation ensures a secure connection, preventing shifting or separation. High-quality bolts and connectors are essential for maintaining the dock’s stability and longevity, especially in harsh marine environments. Regular inspection and tightening are necessary to maintain safety and performance over time.

Maintenance and Repair

Regular inspections and prompt repairs are vital for extending the dock’s lifespan. Check for damage, rot, or corrosion, and address issues quickly to prevent further deterioration.

7.1 Regular Inspection of Floats and Frame

Regular inspections are crucial for maintaining the integrity of your floating dock. Check the floats for leaks, cracks, or damage that could compromise buoyancy. Inspect the frame for signs of rot, corrosion, or structural weaknesses. Ensure all hardware is secure and tighten any loose bolts or brackets. Addressing these issues promptly prevents costly repairs and ensures the dock remains stable and safe. Seasonal inspections, especially before heavy use, help maintain the dock’s condition and longevity. Always prioritize the structural health of both floats and frame to uphold safety and performance.

7.2 Replacing Damaged Decking Boards

Replacing damaged decking boards is vital for maintaining the dock’s appearance and functionality. Remove the damaged boards carefully, ensuring not to harm adjacent sections. Inspect the underlying frame for any damage or rot before installing new boards. Use high-quality, weather-resistant materials, such as cedar or composite decking, to ensure durability; Secure the boards tightly with galvanized screws to prevent movement. Proper alignment and spacing are essential to maintain the dock’s structural integrity and safety. Regularly replacing worn or damaged boards prevents larger, costlier repairs and extends the dock’s lifespan.

7.3 Protecting Against Corrosion and Rot

Protecting your floating dock from corrosion and rot is crucial for its longevity. Regularly inspect the dock frame, floats, and hardware for signs of rust or decay. Apply protective coatings like waterproof sealants or rust-inhibiting paints to metal components. Use pressure-treated lumber for the frame to resist rot. Ensure all hardware is galvanized or made from stainless steel to prevent corrosion. Proper drainage and airflow are essential to prevent water pooling, which can lead to rot. Regular maintenance and timely repairs will ensure your dock remains stable and secure for years to come.

Safety Considerations

Ensure stability and balance for safe access. Install sturdy railings and proper lighting. Regular inspections and secure electrical systems prevent hazards, ensuring a safe environment for all users.

8.1 Ensuring Stability and Balance

Stability and balance are critical for safe floating dock usage. Proper flotation distribution and weight capacity calculation ensure even load distribution. Securely attach floats to the frame, ensuring they are evenly spaced and adequately support the dock’s structure. Regular inspections of flotation materials and frame integrity are essential. Avoid overloading the dock, as this can compromise stability. Ensure the dock is anchored securely to prevent shifting in water. Proper construction and material choice, as outlined in floating dock plans, help maintain balance and safety for all users.

8.2 Proper Use of Safety Railings

Safety railings are essential for preventing accidents on floating docks. Ensure railings are installed securely and meet local safety standards. They should be durable, using materials like cedar or composite decking, and designed to withstand water exposure. Railings must be at a proper height (typically 36 inches) and securely attached to the dock frame. Regularly inspect railings for damage or wear. Proper installation and maintenance ensure the railings provide reliable support and protection, reducing the risk of falls and enhancing overall dock safety for users of all ages.

8.3 Electrical and Fire Safety

Ensure all electrical components on your floating dock meet marine-grade standards to prevent water-related hazards. Install GFCI-protected outlets and keep wiring insulated. Regularly inspect electrical systems for damage or wear. Fire safety is crucial; keep fire extinguishers accessible and avoid open flames. Proper lighting can enhance visibility and safety at night. Always follow local fire safety codes and guidelines. By prioritizing electrical and fire safety, you create a secure environment for everyone using the dock, minimizing risks and ensuring a durable, reliable structure for years to come.

Customization and Upgrades

Customize your floating dock with storage compartments, seating, or lighting. Upgrade materials to premium options like composite decking or stainless steel hardware for enhanced durability and aesthetics.

9.1 Adding Storage or Seating

Enhance your floating dock’s functionality by incorporating storage solutions or seating options. Built-in compartments can store fishing gear, life jackets, or accessories. Benches or foldable chairs provide comfortable seating areas, perfect for relaxing. Use durable materials like cedar or composite decking to ensure longevity. Consider space-saving designs, such as hinged seats with storage underneath. These upgrades not only improve practicality but also elevate the aesthetic appeal of your dock, making it a cozy retreat for leisure activities.

9.2 Incorporating Lighting

Incorporating lighting into your floating dock design enhances safety, ambiance, and functionality. Solar-powered lights are a popular choice, offering energy efficiency and low maintenance. LED lights are another great option, providing bright, long-lasting illumination. Consider installing lights along the dock edges, stairs, or under railings for a modern look. Lighting can also highlight storage areas or seating, improving visibility and aesthetics. Ensure lights are waterproof and securely fastened to withstand marine conditions. Proper lighting not only extends the dock’s usability into the evening but also adds a touch of elegance to your waterfront space.

9.3 Upgrading to Premium Materials

Upgrading to premium materials enhances the durability and aesthetic appeal of your floating dock. Consider using high-grade composite decking for a low-maintenance, weather-resistant surface; Premium polyethylene floats offer superior buoyancy and longevity compared to standard options. For the frame, opt for marine-grade lumber or aluminum for added strength and resistance to rot. Stainless steel hardware ensures long-lasting performance in corrosive environments. These upgrades not only improve the dock’s structural integrity but also provide a sleek, modern appearance that withstands harsh marine conditions, making your dock a lasting investment.

Troubleshooting Common Issues

Identify and address common problems like leaks, instability, or pest damage. Regular inspections and timely repairs ensure your floating dock remains safe and functional for years.

10.1 Addressing Leaks or Water Infiltration

Identify leaks by inspecting the dock frame and floats for cracks or gaps. Use marine-grade sealants or epoxy to repair damaged areas. Ensure all barrels or floats are tightly sealed and securely attached to the frame. Regularly check for signs of water ingress, such as water pooling or soft spots in the decking. Apply a waterproof coating to vulnerable areas as a preventive measure. Addressing leaks promptly prevents structural damage and ensures the dock remains stable and safe for use.

10.2 Fixing Wobbly or Unstable Sections

Inspect the dock frame and connections for loose bolts or brackets. Tighten all hardware and ensure floats are evenly distributed. If instability persists, add stabilizing supports or crossbeams. Check for uneven buoyancy by adjusting float positions or adding additional floats. Ensure the dock frame is square and properly aligned. For severe instability, consider reinforcing the frame with marine-grade lumber or brackets. Regular maintenance and inspections can prevent wobbling and extend the dock’s lifespan. Always use durable, weather-resistant materials for repairs to maintain stability and safety.

10.3 Dealing with Pest or Marine Life Damage

Inspect the dock regularly for signs of pest or marine life damage, such as bored holes or weakened wood. Treat pressure-treated lumber with additional sealants or coatings to deter pests. Replace damaged decking boards promptly to prevent further deterioration. Use marine-grade materials resistant to rot and insect damage. Consider applying epoxy-based coatings or borate-based treatments to protect the wood. Install barriers or mesh around floats to prevent marine life from nesting or causing damage. Addressing these issues early ensures the dock remains structurally sound and safe for years.

Building a floating dock is a rewarding project that enhances water access. With proper planning and execution, your dock will provide years of safety and functionality. Start building today!

11.1 Summary of Key Points

Floating dock plans guide you through materials, tools, and construction steps. Proper design ensures stability, safety, and durability. Regular maintenance and adhering to local regulations are crucial for longevity.

11.2 Encouragement to Start Your Project

Building a floating dock can be a rewarding experience, offering improved water access and enjoyment. With detailed plans and step-by-step guides, you can confidently start your project. Remember, proper planning and execution ensure safety and durability. Don’t hesitate to customize designs to fit your needs. The sense of accomplishment and enhanced waterfront functionality make the effort worthwhile. Gather your materials, follow the instructions, and create a structure that will serve you for years to come. Start your floating dock project today and enjoy the benefits of your hard work!

Be First to Comment